Serving to the markets, finest range of Plates, Tubes, Plastic Machined Components, Rods and Peek Machined Components of Engineering Plastics at rates that are easy to afford...

About Us

We, Vinit Performance Polymers Pvt. Ltd. is a famous company involved in changing new generation engineering plastics into stock shapes, which are used for machining of engineering components performing under difficult conditions of friction, wear, load, thermal/electrical insulation and corrosive environment.

Over two decades, our company has been involved in manufacturing and distributing engineering plastic stock shapes and Plastic Machined Components. Our offered materials like PP, PE's are used for low temperature, whereas PA66, PA6G, POM, PETP, PBT are used for moderate temperature use and PA, PES, PSU, PEI, PVDF and PEEK are used for high temperature use.

Significant Contribution of Stakeholders

Contribution of our stakeholders is one of the major reasons of our growth. We look forward to building the trust resposed in our company as we move ahead to become a famous supplier with focus on performance plastic stock and machines components.

We value the contribution of our stakeholders in our growth over the years and look forward to building on the trust reposed in our company as we march ahead to become a leading quality supplier with focus on performance plastic stock shapes and machined components.

Quality Assurance

Our products are made to high industry standards under quality monitoring regime so as to fulfill the expectation of our customers for worldwide competitiveness. All our products have been widely used for components performing under challenging conditions by industry across manufacturing segments that includes Textile, Transportation, Machine building, Food and Pharma, Energy and Defense, Medical, Components made from our products usually find it's way to global destinations as component of exported machinery.

A Company which Satisfies its Customers

With a determination to satisfy our customers, we have maintained certain attributes, through which we succeed at winning the trust of clients. Any client who comes to us, is impressed by availing our genuine quality product, and by getting treated in a most ethical manner. Some of these are:-

- We never delay the delivery of our products.

- We always price our offerings at rates that suits the budget of customers.

- We never deliver product of less impressive quality than before.

Products Range:

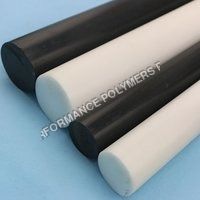

- Engineering Plastic Rods

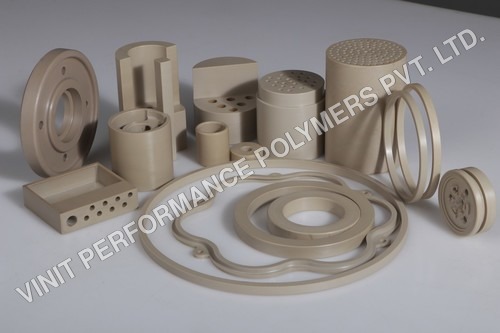

- Engineering Plastic Machined Components

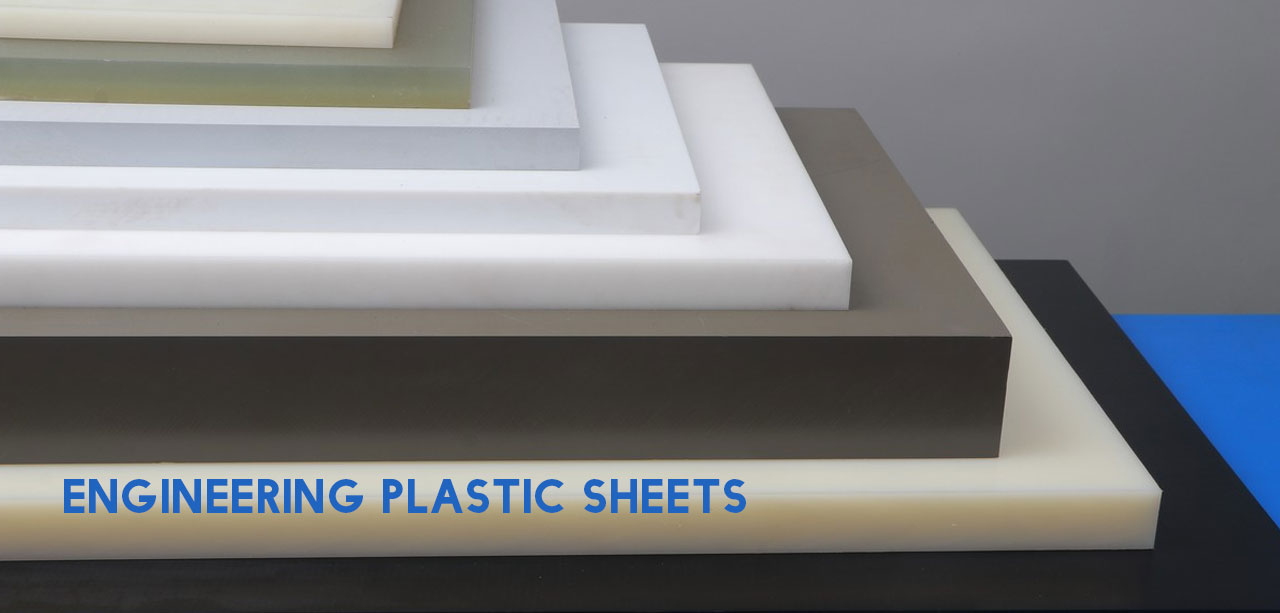

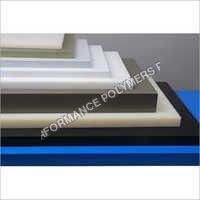

- Engineering Plastic Sheets

- Engineering Plastic Tubes

- Industrial PVDF Sheets

- Industrial PTFE Sheets

- Industrial PVDF Tubes

Our Team

Personnel working in the facility of our company have helped us earn success in this market. It is their efforts, and sincerity in functioning that helps us become a distinct firm. They never compromise with the quality of work, and promise to always help us achieve whatever we seek for. Each one of our employee has rich expertise in their respective domain of work, and ensure to best at whatever we allocate to them. The work done by these personnel sets new standard in the markets, on which new companies look up to, and because of which we have become a priority of customers.

A Company which Satisfies its Customers

We are proud to introduce ourselves as a company which never disappoints its customers. Since the day we started our journey, we have always focused on only one thing, which is to keep our customers content from our end. We do anything and everything in the best of our capability to make the respected customers realize that we are the best choice for them.

-

POLYACETAL ROD -

PVDF ROD -

NYLON 6 ROD -

Peek Rods -

Nylon Sheet -

POLYACETAL Sheet -

Peek Sheets -

Delrin Sheets -

Peek Tubes -

Industrial Plastic Nylon Tube -

Delrin Polyacetal Tube -

PEEK TUBING -

Polyacetal-Delrin Machined Components -

PA 6 Black Machined Components -

Peek Machined Component -

Machined Components -

Cast Nylon Rod -

Plastic Nylon Rod -

White Nylon Rod -

PEEK WASHER -

PEEK Back Up Rings -

Peek O Ring -

Industrial Peek ring -

Peek plate -

Industrial Peek bar -

PEEK ROUND BAR -

PTFE Sheets -

Industrial PTFE Tubes -

PTFE Machined Components -

Industrial PTFE Rods -

Peek Bush -

PEEK Valve Plate -

PVDF Sheet

|

VINIT PERFORMANCE POLYMERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |